The following are the applications of DELMIA:

COLLABORATIVE OPERATIONS

DELMIA Collaborative Operations is the cornerstone of the 3DEXPERIENCE Operations vision. With that vision comes Lean practices-- a standard part of business, building better team relationships and visualizing 3D content and data within a digital framework. While enabling a common understanding for all stakeholders, DELMIA 3DLean addresses different team challenges and goals to continuously improve operational efficiency by empowering teams to find new ways to innovate together. Users will realize the value of teams working in any function, as well as cross-functional teams along with the framework to guide collaboration and improve team performance. Efficient collaboration through lean practices is achieved by digitally connecting users so companies can have visibility into, control over, and synchronization across their enterprise.

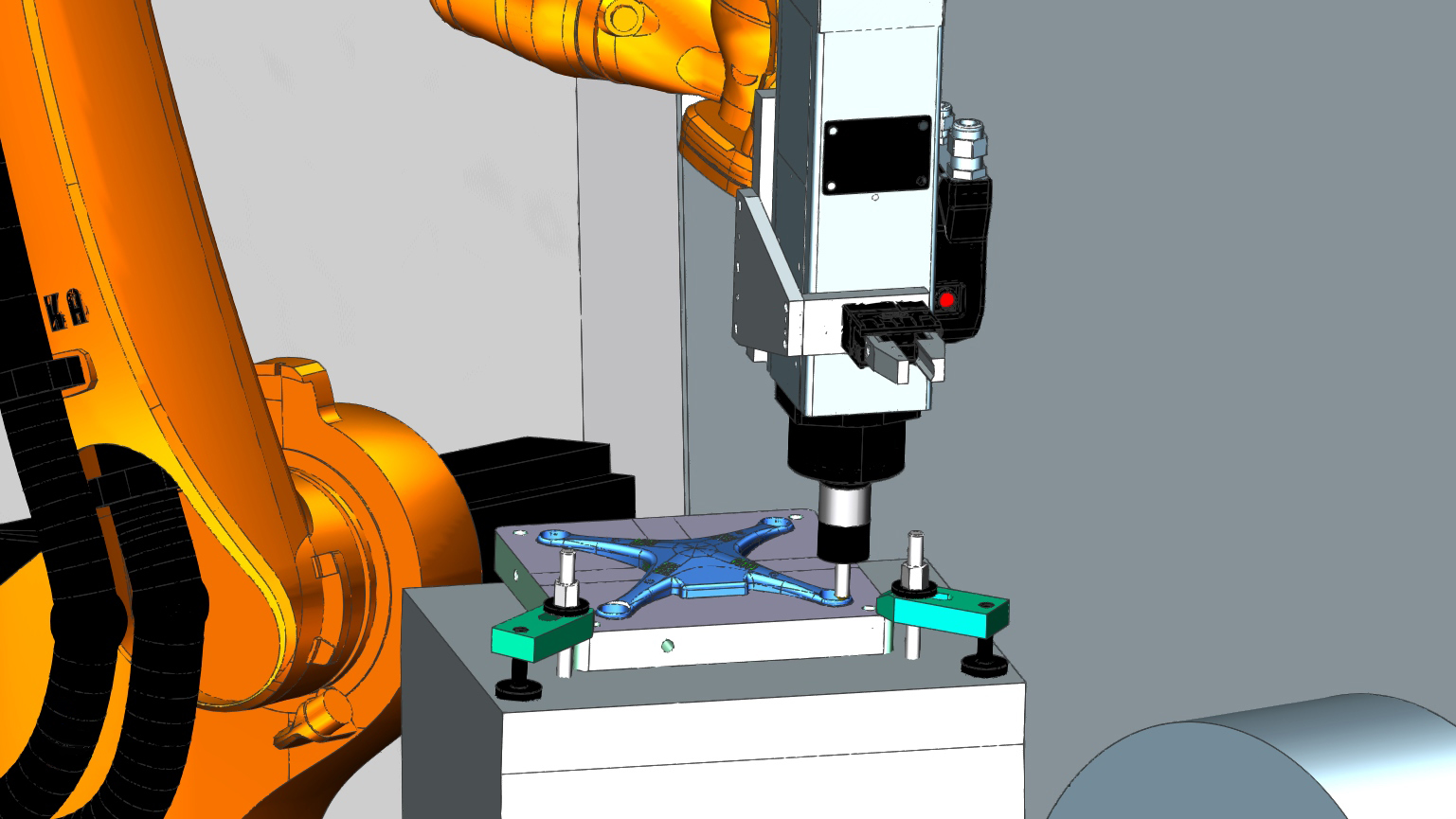

INDUSTRIAL ENGINEERING

DELMIA Industrial Engineering enables innovation and efficiency by planning, simulating, and modeling global operations. DELMIA allows manufacturing and service providers to virtually experience their entire operations from the impact of design to determining how to meet global demand. This is made possible with a single 3D data model across operations--spanning engineering, manufacturing, logistics and service. Customers can virtually validate value networks, factory layouts, transportation plans, process plans, logistics plans and workforce plan to quickly respond to the competition or new market opportunities. For manufacturers, capabilities extend visualization beyond the product into manufacturing and operations--simulating manufacturing processes before the physical plant or production line even exists.

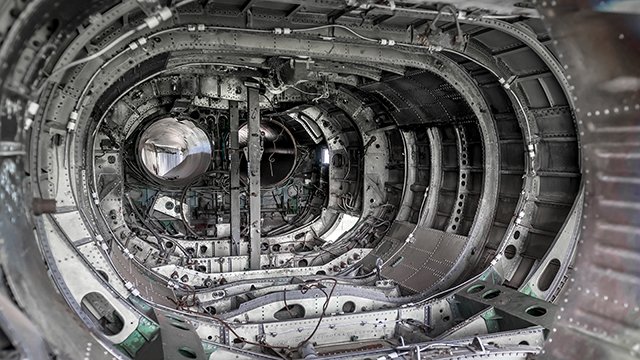

MANUFACTURING & OPERATIONS

DELMIA Manufacturing & Operations solutions transform global operations to achieve and sustain operational excellence. This is accomplished through digital continuity, a shared digital landscape connecting all stakeholders to improve visibility into, control over and synchronization across manufacturing operations and supply chain processes on a global scale. The result is improved agility and expanded continuous improvement across the enterprise and extended value network. By providing a model-based, data-driven digital user experience, customers can establish a common set of operational processes that can be created, managed, and governed holistically on a global scale.

SUPPLY CHAIN PLANNING & OPTIMIZATION

DELMIA Supply Chain Planning and Optimization powers reality-based planning, scheduling and optimization for complex business processes within manufacturing, logistics, transit and workforce operations--across all planning horizons. Built around a 100%-fit model, it's configured to respect all of an organization's unique rules and constraints, such as production capacity, inventory and logistics constraints, contractual requirements and more. At the same time, it's flexible enough to rapidly adapt to the peaks and troughs of day-to-day operations. The result is feasible plans, optimized against key performance indicators, always in sync with the realities of the business.DELMIA customers rely on the same fully integrated 100%-fit planning and optimization solution to plan their workforce, manufacturing environment and logistics operations.